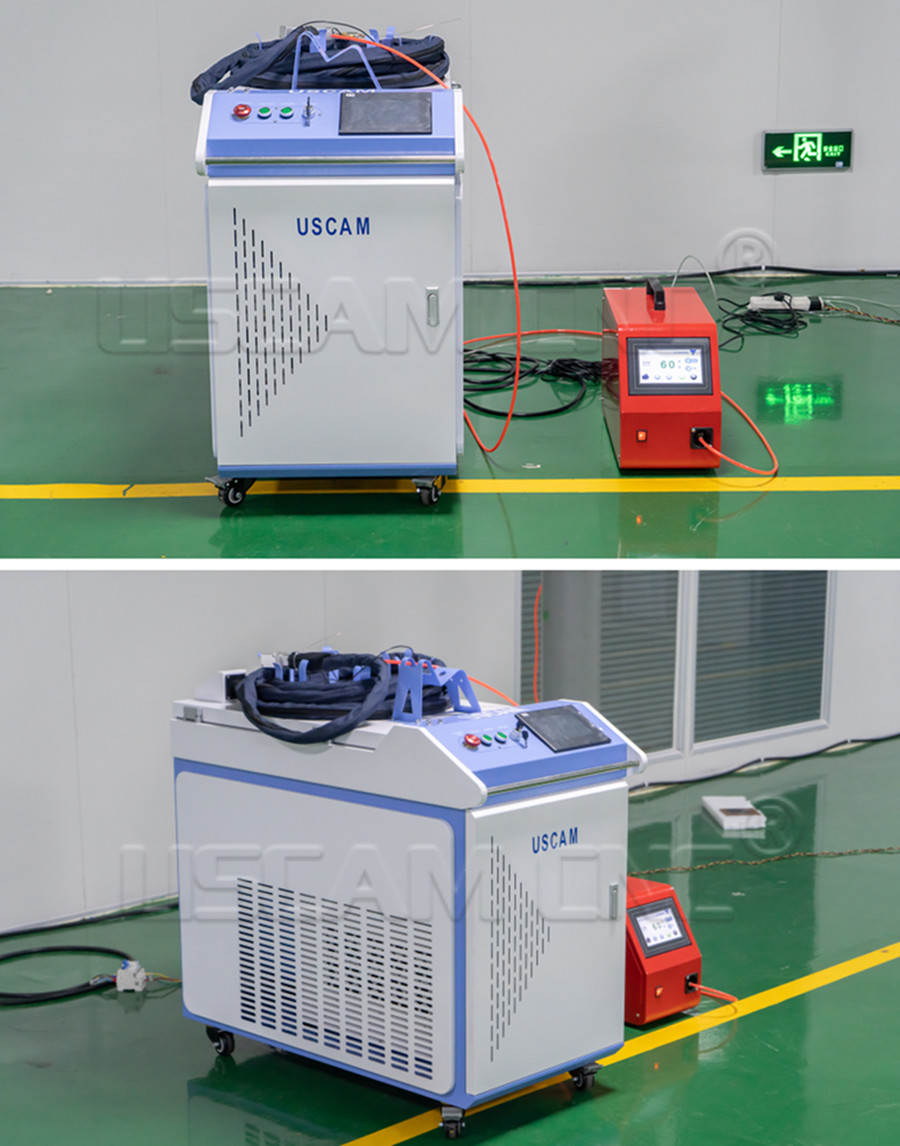

USCAM is seldom company which can research and develop the whole set of hand torch welding machine : Hand torch welding head→Laser control system→Wobble control system→Feeding device. Self-develop the full set and put on the market. Products with ergonomic concept and design, think through the welding technology applicability and comfort for long-term use (Weight 0.8 kg). And have the safety lock: Output the laser only when the nozzle touch the workpiece to prevent harming others. Adopt drawer type of protection lens setting for convenience of users themselves for a replacement.

The hand torch head can configure different angle of nozzle. The head support 2000W laser power maximum to meet the different requirements of customers. The laser output with swing effect, Enlarged the work piece tolerance range and welding width, solved disadvantage of small and tiny laser spot.

Product Description

USCAM is seldom company which can research and develop the whole set of hand torch welding machine : Hand torch welding head→Laser control system→Wobble control system→Feeding device. Self-develop the full set and put on the market. Products with ergonomic concept and design, think through the welding technology applicability and comfort for long-term use (Weight 0.8 kg). And have the safety lock: Output the laser only when the nozzle touch the workpiece to prevent harming others. Adopt drawer type of protection lens setting for convenience of users themselves for a replacement. The hand torch head can configure different angle of nozzle. The head support 2000W laser power maximum to meet the different requirements of customers. The laser output with swing effect, Enlarged the work piece tolerance range and welding width, solved disadvantage of small and tiny laser spot. |

Product Advantages: 1.Support welding parameter save2.CW, Adjust, Argon type, QCW(Pulse welding) Four welding types. 3.Setting wire feeder's digital parameter in monitor. 4.The language include Chinese, English, Korean, Japanese, Russian. 5.The system real-time monitoring condition at operation : Laser source, Water chiller, Control board. 6.Perfect substitute argon welding and electric welding in thin metal material welding area. Like stainless steel, carbon steel, aluminum and etc. 7.Light weight, Small size, Ergonomic design for handling comfort. 8.Safety lock touch for output laser. 9.Easy operation, low requirements for operator. Strong Anti-jamming. 10.The entire seal structure. Internal water and gas route. 11.Adopt independent R&D control system. 12500W-2000W;Strong anti-jamming, configuration 500W-2000W laser source. |

| Parameter | |

| Model | USW-1000W/USW1500W/USW2000W/(USJ-1000W/USJ-1500W/USJ-2000W) |

| Laser power | 1000W/1500W/2000W |

| Focal length | 150/200 |

| Collimate focus | 60/80 |

| Interface type | QBH |

| Accessible wave range | 1064 |

| Net weight | 0.8kg |

| (mm) Light source diameter(mm) | 1.0,2.0,3.0(Option) |

| Usable laser source | All of laser source |

| Control system | Chaoqiang/Hanwei |

| System | M-V6 .02 V6.04 |

| Driver | 40*105-DC24V Second Version |

| Laser type | Continious type |

| Fiber cable length | 8m/10m |

| Cooling type | Water cooling |

| ctricity demand | AC 220V/380V±10%/50Hz |

| Feeding device | Yes |

| NO | Name | Qty | NO | Name | Qty |

| 1 | Laser welding head | 1 | 12 | Chiller error wire | 1 |

| 2 | Internal corner welding 2.0 nozzle | 1 | 13 | Handtorch gun control wire | 1 |

| 3 | U type Nozzle 2.0 | 1 | 14 | Safety capacity X | 1 |

| 4 | U type nozzle 2.0 | 1 | 15 | Power switch | 1 |

| 5 | Protection lens | 2 | 16 | Wire feeder | 1 |

| 6 | Clip | 1 | 17 | Wire feeder power supply wire | 1 |

| 7 | Monitor | 1 | 18 | Wire feeder control wire | 1 |

| 8 | Monitor wire | 1 | 19 | Wire feeding structure | 1 |

| 9 | PCB board | 1 | 20 | Wire feeding nozzle 2.o | 1 |

| 10 | Wobble driver | 1 | 21 | Wire feeding roller | 1 |

| 11 | HZ-043A-2 Noise Filter | 1 |

| Continuous mode welding | ||||||

| thickness(mm) | Laser power(W) (Welding/penetration) | Swing speed (%) | wire feed speed | Return speed | Wire diameter (mm) Welding wire available | |

| SS | 1 | 420/600 | 100/100 | 14/13 | Depends on the situation | 0.8 |

| 1.5 | 500/680 | 100/100 | 14/13 | Depends on the situation | 0.8 | |

| 2 | 650/1000 | 100/100 | 13/12 | Depends on the situation | 0.8/1.0/1.2/1.6 | |

| 2.5 | 700/1100 | 100/100 | 13/12 | Depends on the situation | 0.8/1.0/1.2/1.6 | |

| 3 | 750/1450 | 100/100 | 12/11 | Depends on the situation | 0.8/1.0/1.2/1.6 | |

| 3.5 | 900/1400 | 100/100 | 12/11 | Depends on the situation | 0.8/1.0/1.2/1.6 | |

| 4 | 1000/1500 | 100/100 | 11/10 | Depends on the situation | 0.8/1.0/1.2/1.6 | |

| 4.5 | 1150/1650 | 100/100 | 11/10 | Depends on the situation | 0.8/1.0/1.2/1.6 | |

| 5 | 1250/1700 | 100/100 | 10/9 | Depends on the situation | 0.8/1.0/1.2/1.6 | |

| CS | 1 | 420/600 | 100/100 | 14/13 | Depends on the situation | 0.8 |

| 1.5 | 500/680 | 100/100 | 14/13 | Depends on the situation | 0.8 | |

| 2 | 650/1000 | 100/100 | 13/12 | Depends on the situation | 0.8/1.0/1.2/1.6 | |

| 2.5 | 700/1100 | 100/100 | 13/12 | Depends on the situation | 0.8/1.0/1.2/1.6 | |

| 3 | 750/1450 | 100/100 | 12/11 | Depends on the situation | 0.8/1.0/1.2/1.6 | |

| 3.5 | 900/1400 | 100/100 | 12/11 | Depends on the situation | 0.8/1.0/1.2/1.6 | |

| 4 | 1000/1500 | 100/100 | 11/10 | Depends on the situation | 0.8/1.0/1.2/1.6 | |

| 4.5 | 1150/1650 | 100/100 | 11/10 | Depends on the situation | 0.8/1.0/1.2/1.6 | |

| 5 | 1250/1700 | 100/100 | 10/9 | Depends on the situation | 0.8/1.0/1.2/1.6 | |

| Aluminium | 1 | 550/500 | 20/20 | 14/13 | Depends on the situation | 0.8 |

| 1.5 | 650/700 | 20/20 | 14/13 | Depends on the situation | 0.8/1.0/1.2 | |

| 2 | 700/750 | 20/20 | 13/12 | Depends on the situation | 0.8/1.0/1.2 | |

| 2.5 | 800/850 | 20/20 | 13/12 | Depends on the situation | 0.8/1.0/1.2 | |

| 3 | 850/1000 | 20/20 | 12/11 | Depends on the situation | 0.8/1.0/1.2 | |

| 3.5 | 1250/1300 | 20/20 | 12/11 | Depends on the situation | 0.8/1.0/1.2 | |

| 4 | 1450/1500 | 20/20 | 11/10 | Depends on the situation | 0.8/1.0/1.2 | |

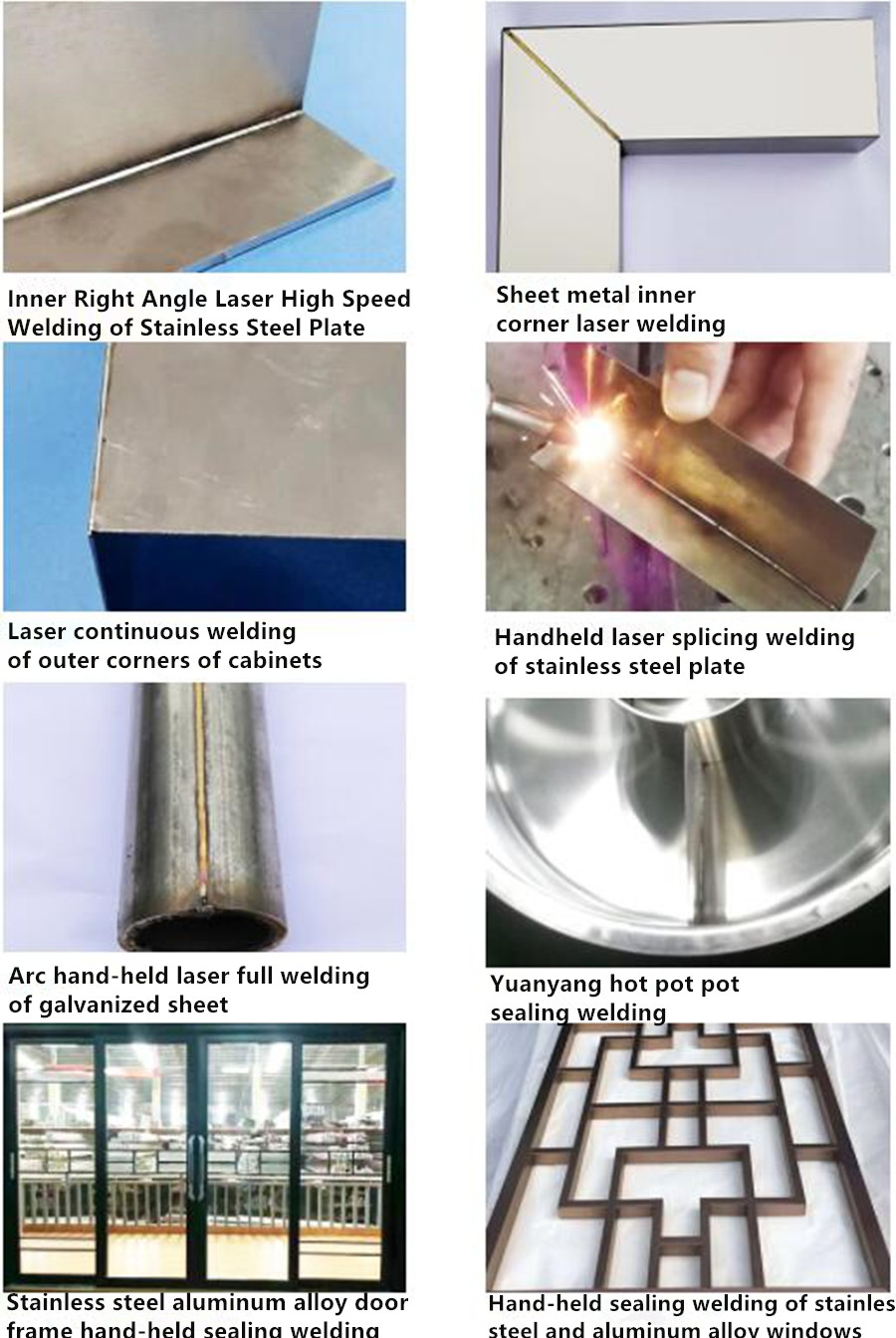

Application

Mold laser welding machine widely used in molds, precision injection molding, die castng and punching mold, stainless steel products and other hard materials cracks, chipping, grinding and wear seal repair, welding, cell phones, jewelry, electronics, sensors, precision machinery, communications,crafts and other industries.

Certifications & Sevice

QC

Having been export to USA, Europe, Africa, Central America, Latin America, Mexico, UAE, Yemen, Pakistan, India, Korea, etc.

We have CE, FDA certification for easy exporting and importing.

After Sales Service

# 18 months-quality guarantythe machine with main parts(excluding the consumables) shall be changed free of charge if there is

any problemduring the warranty period without human damage.

# We will provide the consumable parts at an agency price when you need replacement.

# 24 hours on line service each day, by wechat, QQ, e-mail, cellphone or remotely controlled online.

# Lifetime patience and professional question and answer service(free technical support), even if it exceeds the warranty period.

# English manual and video for machine using and maintaining will send to you with the machine.

# Free training course at our plant.

# Our staff can be sent to your company to install or adjust if necessary.

Maintenance

1) Protection lens Maintenance and replacement

# Protection lens at the bottom of focusing lens, when inclusion and foreign material on the protection lens may absorb laser

and become heating to cause protection lens damage. So need regular clean the protection lens.

# Suggest cleaning period : One week. The protection lens as consumable materials, after damage need exchange new one.

# Caution: When cleaning and exchanging the protection lens, avoid the grease and dust to pollute the protection lens.

Packaging & Shipping

3 layers packages:

Inside layer: the machine is covered by thickening plastic bag for waterproof.

Middle layer: the machine is covered by foam, to protect the machine from shaking.

Outside layer: it adopts strong plywood case with export standard.

1. wood case, its compressive strength and bearing quality is better.

2. the board area is bit, the soil structure is good, it is better in leakproofness and waterproof.

3. when importing, the plywood case is with fumigation-free, the procedure is simple.

4. Delivery Detail: within 7-15 days after received your payment

Customers' feedback

| # Customers are using machines very well and almost no problem. # Always get returned orders from agents and customers. # 10 points of praise for service from our customers

|

Company Profile

| USCAM specialized in in fiber laser cutting machine, laser marking machine, laser cleaning machine, laser welding machine, co2 laser, CNC router (ATC, Stone machine, molding machine, vibrating knife etc), plasma (gantry plasma, 5 axis, 8 axis and robort plasma etc) and other fields are the leading companies in China's laser industry since 2003. All machines have passed CE FDA certification, and the main configuration adopts top components imported from Italy, Japan, Germany, the United States, etc., such as Synrid, Coherent, HSD spindle, THK bearing system, Siemens control system, YASKAWA servo. Relying on strong high-tech strength, it has been highly recognized by relevant international quality systems and government departments in product software research and development, quality inspection files, etc. High-quality products and excellent after-sales service have enabled the company to reach an excellent level, and have been widely supported by customers and agents. |

| FAQ |

Q1: How to install and run the machine?

A1: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training

video, user's manual along with the machine. 95% customers can learn by themselves.

Q2: How can I do if the machine goes wrong?

A2: If confronted with such problems, please contact us asap and do not try fix the machine by yourself or someone else. We

will response within 2 hours as quick as we can to solve it for you.

Q3: what's the Payment term ?

A3:30% T/T in advance and 70% before delivery.

Q4: What's the process of the order ?

1).Proforma Invoice

If you like the machine we offered, then we will make you an Proforma Invoice. Then you could pay 30% T/T in advance, thus

we arrange the production for you immediately.

2).Production:

After the 30% T/T as deposit, we will produce the machine immediately, then after after it finished, we will take video test and

pictures for you. If you agree, you could pay the balance.

3).Shipping matter:.

You could ship with your own shipper if it's convenient. and we could help to ship for you.

| Feel free to contact Grace: export01@uscamcnc.com; whatsapp: +8613645319835 |

Wood CNC Router, please feel free contact Grace. My pleasure to help you. :):)