Instruction:

Laser cleaning equipment is a new generation of high-tech surface treatment products, which are easy to install, operate and

realize automation. The operation is simple, the power is turned on, and the equipment is turned on to perform cleaning without

chemicals, media, dust, and water. It can be cleaned on curved surfaces. The cleaning surface has a high degree of cleanliness.

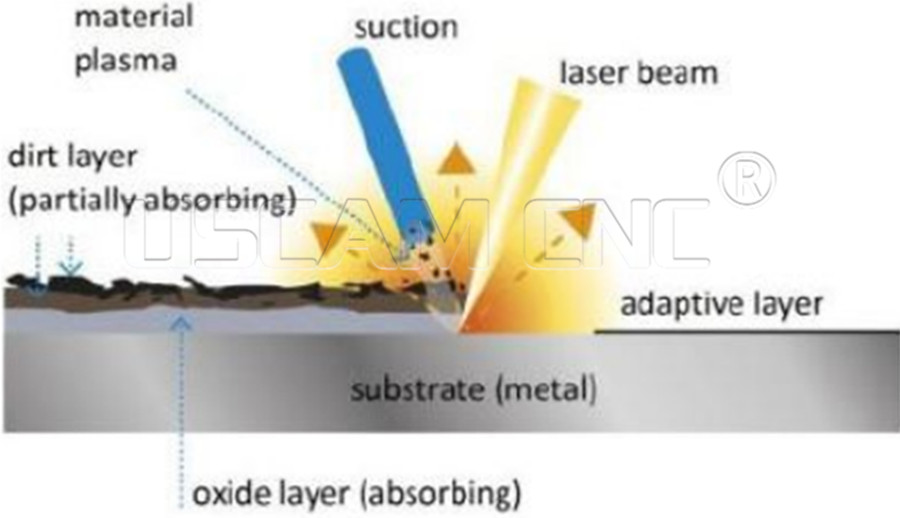

It can remove resin, paint, oil, and dirt on the surface of the object. Dirt, dirt, rust, coating, plating and oxide layer, and are widely

used in the industry, covering ships, auto repair, rubber molds, high-end machine tools, rails, and environmental protection. USCAM Laser cleaning machine features

USCAM Laser cleaning machine features

Non-contact cleaning, does not damage the part matrix;

Precise cleaning, can achieve precise location, precise size selective cleaning;

No chemical cleaning fluid, no consumables, safety and environmental protection;

Simple operation, can be hand-held or cooperated with a manipulator to realize automatic cleaning;

Ergonomic design, greatly reducing the labor intensity of operation;

The laser cleaning system is stable, almost no maintenance;

Basic configuration

Power: 500w 1000w from JPT

Mode of operation: Handheld/Automated

Air cooling system

Scanning range (length * width) Single axis: 5mm~120mm

Scanning frequency 10Hz~300Hz

Field lens focal length (mm) 160mm (optional 100mm~500mm)

Depth of focus max. 15mm

Size: 800mm×650mm×370mm(0.2CBM)

Weight: 56kg

Weight of cleaning head (including isolator) about 2KgPower supply voltage Single phase 220V±10%, 50/60Hz AC

Product Parameters

| Model | USC-1000w/1500w/2000w CNC laser cleaning machine |

| Power | 1000w/1500W/2000w |

| Laser Type | Continuous Fiber Laser Generator |

| Wavelength | 1064nm |

| Maximum Marking Line | 150mm |

| Gross Power | 0.5kwH |

| Warranty | 2 Year |

| Pulse energy | 1.5mJ |

| Peak power | 15kW |

| Head Weight | Standard head:1.8kg, Anti-shake head:2.0kg |

| Scan width | 5mm-175mm (Customized)Continuously Adjustable |

| Cooling | Air Cooling |

| Cleaning paint/rust | 8.0m2/h |

| Cleaning oil | 9.0m2/h |

| Titanium alloy/stainless Steel oxide | 8.0m2/h |

| Cleaning aluminum alloy oxide film | 6.0m2/h |

| Operating environment | |

| Content | parameter |

| Power supply voltage | Single-phase 220V±10%, 50/60Hz AC |

| System power consumption | less than 120W |

| Working environment temperature | -10ºC~40ºC |

| Working environment humidity | ≤80% |

| Optical parameters | |

| Can withstand laser average power | ≤2000W |

| Light pass rate | ≥98% |

| Laser power adjustment | 10%-100% continuous gradual adjustment |

| Laser pulse frequency adjustment | 1kHz-2000kHzcontinuous gradual adjustment (support customization) |

| Laser pulse width adjustment function | support |

| Focal length | 500mm |

| Cleaning head, galvanometer, field lens parameters | |

| Cleaning head size | as shown in figure 2.3/2.4 |

| Washing head weight | less than 1.2Kg(excluding QBH) |

| Scanning width | up to 200*100mm,continuously adjustable |

| Scanning frequency | The max will be not less than 300Hz |

| Maximum scanning line speed | MAX 20m/s |

| Vibration lens material | Quartz |

| Mirror material | Quartz |

| Field lens material | Quartz |

| Other parameters | |

| Screen size | Standard 7 inches (optional 4.3 inches) + 2.8 inches front. |

| Cable length | standard 10 meters |

| Mode of operation | handheld/automated |

Detailed Photos

Application

It can remove resin, paint, oil, and dirt on the surface of the object. Dirt, dirt, rust, coating, plating and oxide layer, and are widely

used in the industry, covering ships, auto repair, rubber molds, high-end machine tools, rails, and environmental protection.

Certifications & Sevice

QC

Having been export to USA, Europe, Africa, Central America, Latin America, Mexico, UAE, Yemen, Pakistan, India, Korea, etc.

We have CE, FDA certification for easy exporting and importing.

After Sales Service

# 18 months-quality guarantythe machine with main parts(excluding the consumables) shall be changed free of charge if there is

any problemduring the warranty period without human damage.

# We will provide the consumable parts at an agency price when you need replacement.

# 24 hours on line service each day, by wechat, QQ, e-mail, cellphone or remotely controlled online.

# Lifetime patience and professional question and answer service(free technical support), even if it exceeds the warranty period.

# English manual and video for machine using and maintaining will send to you with the machine.

# Free training course at our plant.

# Our staff can be sent to your company to install or adjust if necessary.

Packaging & Shipping

3 layers packages:

Inside layer: the machine is covered by thickening plastic bag for waterproof.

Middle layer: the machine is covered by foam, to protect the machine from shaking.

Outside layer: it adopts strong plywood case with export standard.

1. wood case, its compressive strength and bearing quality is better.

2. the board area is bit, the soil structure is good, it is better in leakproofness and waterproof.

3. when importing, the plywood case is with fumigation-free, the procedure is simple.

4. Delivery Detail: within 7-15 days after received your payment

Customers' feedback

| # Customers are using machines very well and almost no problem. # Always get returned orders from agents and customers. # 10 points of praise for service from our customers |

Company Profile

| USCAM specialized in in fiber laser cutting machine, laser marking machine, laser cleaning machine, laser welding machine, co2 laser, CNC router (ATC, Stone machine, molding machine, vibrating knife etc), plasma (gantry plasma, 5 axis, 8 axis and robort plasma etc) and other fields are the leading companies in China's laser industry since 2003. All machines have passed CE FDA certification, and the main configuration adopts top components imported from Italy, Japan, Germany, the United States, etc., such as Synrid, Coherent, HSD spindle, THK bearing system, Siemens control system, YASKAWA servo. Relying on strong high-tech strength, it has been highly recognized by relevant international quality systems and government departments in product software research and development, quality inspection files, etc. High-quality products and excellent after-sales service have enabled the company to reach an excellent level, and have been widely supported by customers and agents. |

| FAQ |

Q1: How to install and run the machine?

A1: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training

video, user's manual along with the machine. 95% customers can learn by themselves.

Q2: How can I do if the machine goes wrong?

A2: If confronted with such problems, please contact us asap and do not try fix the machine by yourself or someone else. We

will response within 2 hours as quick as we can to solve it for you.

Q3: what's the Payment term ?

A3:30% T/T in advance and 70% before delivery.

Q4: What's the process of the order ?

1).Proforma Invoice

If you like the machine we offered, then we will make you an Proforma Invoice. Then you could pay 30% T/T in advance, thus

we arrange the production for you immediately.

2).Production:

After the 30% T/T as deposit, we will produce the machine immediately, then after after it finished, we will take video test and

pictures for you. If you agree, you could pay the balance.

3).Shipping matter:.

You could ship with your own shipper if it's convenient. and we could help to ship for you.

| Feel free to contact Grace: export01@uscamcnc.com |

Wood CNC Router, please feel free contact Grace. My pleasure to help you. :):)