Small cnc plasma cutting table only with low price cut stainless steel

1.Introduction of Plasma cutter:

A plasma arc cutting machine is a machine that processes metal materials with the help of plasma cutting technology.

Plasma cutting is a processing method that uses the heat of a high-temperature plasma arc to melt (and evaporate) the metal part or part of the incision of the workpiece, and remove the molten metal by the momentum of high-speed plasma to form an incision.

2.Plasma cutting machine structure

1. The frame adopts fully welded structure, which is sturdy and reasonable, easy to operate and durable.

2. Fast cutting speed and high precision. The cutting opening is small and neat, and there is no slag drop phenomenon. On the basis of the traditional numerical control system, the control method for cutting has been improved to avoid secondary trimming.

3. It is suitable for low carbon steel plate, copper plate, iron plate, aluminum plate, galvanized plate, titanium plate and other metal plates.

4. The CNC system configuration is high. Automatic arc ignition, stable performance, arc ignition success rate of more than 99%.

5. Support standard G code path files generated by Wentai, Beihang Haier, ARTCAM, Type3 and other software. The control system adopts U disk to exchange processing files, which is convenient and quick to operate.

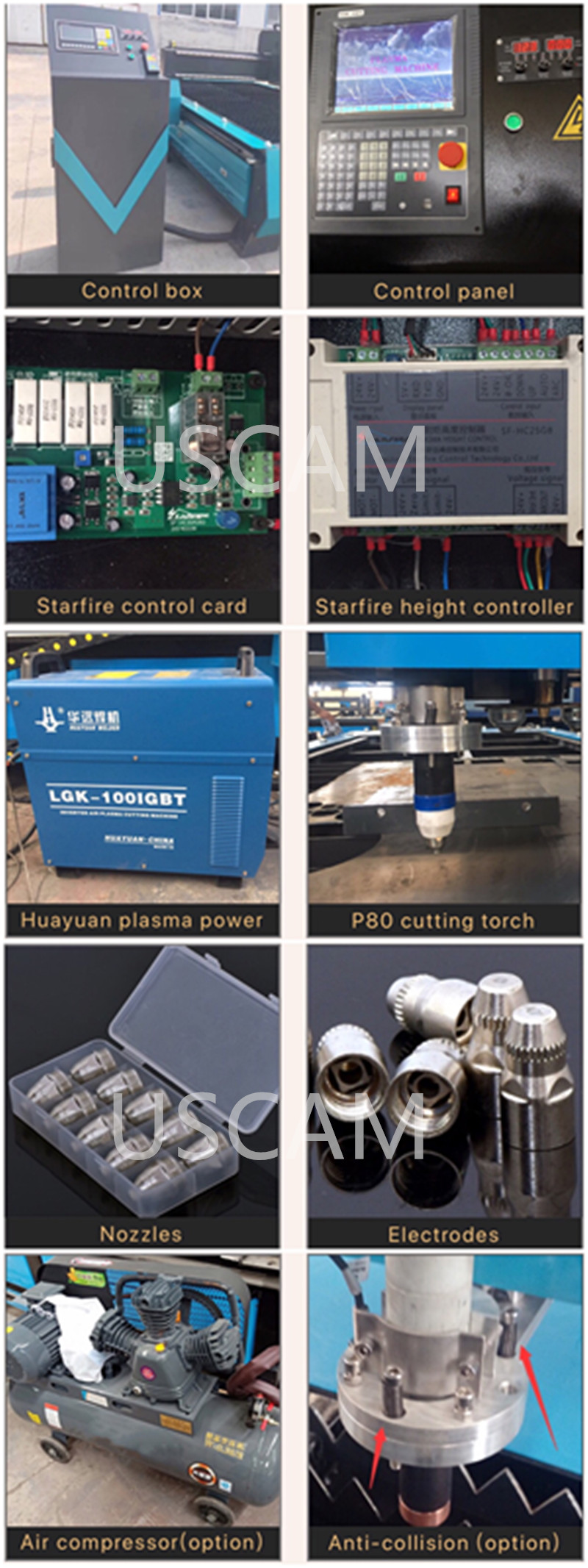

3. Basic configuration of CNC Plasma

- Working area: 1300x2500mm/1500x3000mm/2000x3000mm

- 63A/100A/120A/160A/200A/300A HUAYUAN plasma power supply

- Starfire control system from Beijing

- Starcam original special plasma software

- Leadshine driver and Stepper motor

- Taiwan HIWIN square rail guide

- table: heavy duty steel frame

- FOB Port of loading: QINGDAO port.

- Your estimated delivery time: 7 working days after receiving the deposit

- New design strong body type

- Optional parts: falme head, drilling head, marking head,air compressor

4.Parameter CNC plasma machine:

| NO. | Description | Parameter |

| 1 | X,Y Working Area | 1300*2500mm/1500x3000mm |

| 2 | Table Size | 3070*1970mm |

| 3 | X,Y Traveling Positioning Accuracy | ±0.02mm |

| 4 | X,Y repositioning Accuracy | ±0.01mm |

| 5 | Table | Steel table |

| 6 | Frame | Steel frame |

| 7 | X,Y Structure | Taiwan HIWIN Rail and rack gear |

| 8 | Power supply | 63A/100A/120A/160A/200A/300A Huayuan power supply |

| 9 | Drive Motors | Stepper system |

| 10 | Working Voltage | AC380V/50/60Hz |

| 11 | Command Language | G code |

| 12 | Operating System | Starfire Control System |

| 13 | Interface | USB |

| 14 | Flash Memory | 128M( U Disk) |

| 15 | X,Y Resolution | <0.01mm |

| 16 | Software Compatibility | Starcam(FastCAM) software |

| 17 | Running Environment | Temperature: 0ºC~45ºC Relative humidity: 30%~75% |

| 18 | Packing Size | 3170x2070x1800mm |

| 19 | Net/Gross Weight | 1600KG / 1800KG |

| 20 | Optional parts | Flame head/air compressor |

Application

The plasma cutting machine can cut various metals that are difficult to cut by oxygen cutting with different working gases, especially for non-ferrous metals (aluminum, copper, titanium, nickel), the cutting effect is better; such as stainless steel, carbon steel, mild steel iron plate, aluminum plate, plated,copper etc. And could add flame head for cutting more thicker metal within 300mm.

Thus it is widely applied in industries such as machinery, automobile, shipbuilding, petro-chemical, war industry, metallurgy, aerospace, boiler and pressure vessel, locomotive etc.

The main advantage of zinc plate, white steel plate and titanium plate is that when cutting metal with small thickness, the plasma cutting speed is fast, especially when cutting ordinary carbon steel sheet, the speed can reach 5~6 times of oxygen cutting method. The surface is smooth, the thermal deformation is small, and there is almost no heat affected zone.

Choose a right plasma source according to your cutting thickness:

| Item | Unit | Models | |||||

| LGK-63IGBT | LGK-100IGBT | LGK-120IGBT | LGK-200IGBT | LGK-300IGBT | LGK-400IGBT | ||

| Input Power | V/Hz | 3~ 380V± 15% 50/60 Hz | |||||

| Rated Input capacity | KVA | 9.5 | 17.8 | 22.2 | 38.8 | 70.1 | 93.5 |

| Rated Input Current | A | 14.5 | 27 | 34 | 71 | 100 | 138 |

| Rated Open Circuit Voltage | V | 300 | 300 | 300 | 315 | 380 | 380 |

| Rated Cutting Current | A | 63 | 100 | 120 | 200 | 300 | 400 |

| Rated Cutting Voltage | V | 106 | 120 | 128 | 160 | 200 | 200 |

| Current Adj Range | A | 30~63 | 30~100 | 30~120 | 40~200 | 60~300 | 60~400 |

| Max Cut Thickness(Steel) | mm | 25 | 40 | 45 | 65 | 80 | 90 |

| Quality Cutting Thickness (Steel, hand-held) | mm | 0.3~12 | 0.3~22 | 0.3~25 | 1~45 | 1~50 | 1~50 |

| Quality Cutting Thickness (Steel, machine) | mm | 8 | 15 | 15 | 25 | 30 | 40 |

| Plasma gas | - | Compressed Air | |||||

| Air Pressure | Mpa | 0.3~0.5 | 0.45~0.6 | 0.45~0.6 | |||

| Output Signal of Arc Voltage | - | 1: 1 / 1: 20 1: 50 / 1: 100 Arc Voltage | |||||

| Cutting Torch Cooling Mode | - | Air cooling | Air cooling/Water cooling | ||||

| Rated Duty Cycle | % | 60/40° C | 100/40° C | ||||

| Insulation Grade | - | F | |||||

| Protection Grade | - | IP21S | |||||

| Dimensions(L× W× H) | mm | 585x280x485 | 695× 320× 580 | 800× 380× 810 | 890× 420× 900 | ||

| Power Source N. W. | Kg | 26 | 51 | 52 | 82 | 140 | 145 |

8.Maintainance of CNC machine plasma:

1. Assemble the torch correctly

Install the torch correctly and carefully, making sure that all parts fit together well and that the gas and cooling air flow. Installation Put all parts on a clean flannel to prevent dirt from sticking to the parts.

2. Consumable parts should be replaced in time before they are completely damaged

Do not replace the consumable parts after they are completely damaged, because the severely worn electrode, nozzle and swirl ring will generate an uncontrollable plasma arc, which can easily cause serious damage to the cutting torch. Therefore, the consumable parts should be inspected in time when the cutting quality is found to be degraded for the first time.

3. Clean the connection thread of the torch

When replacing consumables or routine maintenance and inspection, be sure to ensure that the internal and external threads of the torch are clean, and if necessary, clean or repair the connecting threads.

4. Clean the contact surface between the electrode and the nozzle

In many cutting torches, the contact surface between the nozzle and the electrode is an electrified contact surface. If these contact surfaces are dirty, the cutting torch will not work properly and should be cleaned with a hydrogen peroxide type cleaning agent.

5. Check gas and cooling gas daily

Check the flow and pressure of the gas and cooling airflow daily, and if you find insufficient flow or leaks, shut down immediately to troubleshoot.

6. Avoid torch collision damage

In order to avoid the collision damage of the cutting torch, it should be programmed correctly to avoid the system running beyond the limit, and the installation of the anti-collision device can effectively avoid the damage of the cutting torch during collision.

7. Precautions

(1) Do not apply grease to the torch.

(2) Do not overuse the O-ring lubricant.

(3) Do not spray anti-splash chemicals while the protective sleeve is still on the torch.

(4) Do not use the manual torch as a hammer

9.Packing and Shipping matter:

1)Packing: After 30% payment, we will produce the machines for you and after it finished, we will take video test and pictures for you.

After you think is ok, we will pack carefully with strong wood box, which is export standard wood box.

2).Shipping: You could ship with your own shipper if it's convenient. and we could help to ship for you.

After-sales Service:

1. 12months-quality guarantythe machine with main parts(excluding the consumables) shall be changed free of charge if there is any problem during the warranty period without human damage.

2. Free training course at our plant.

3. We will provide the consumable parts at an agency price when you need replacement.

4. 24 hours on line service each day, free technical support.

5. Our staff can be sent to your company to install or adjust if necessary.

6. User-friendly English manual and video CD for machine using and maintaining

7. My company English software can do all kinds of pattern recognition,software upgrading and updating free